Vanke Pavilion at Expo 2015

John Hill

4. 五月 2015

Photo: Studio Daniel Libeskind

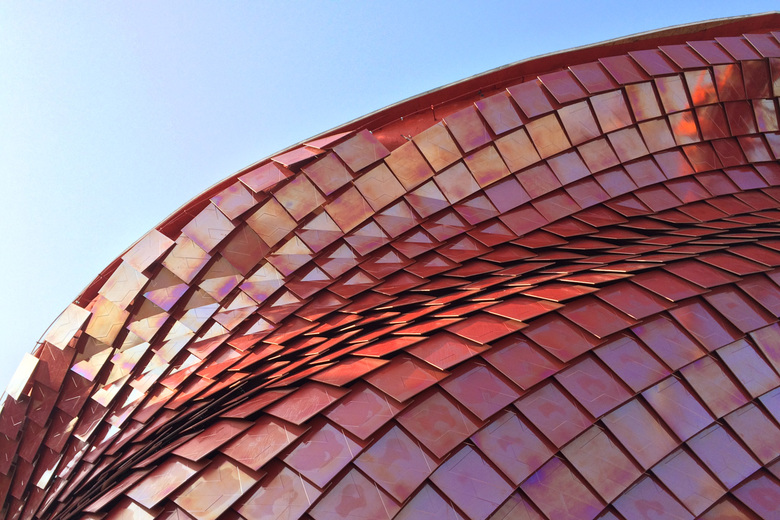

China's presence at the recently opened Expo Milano 2015 is threefold, with a national pavilion, the China Corporate United Pavilion, and the Vanke Pavilion. The last, designed by Daniel Libeskind, is covered in ruby red ceramic tiles developed with Casalgrande Padana.

The pavilion of Vanke, the largest residential real estate developer in China, is grouped with other corporate pavilions, like Coca-Cola and Alitalia, on the Expo grounds near Lake Arena and the Tree of Life. In response to the Expo theme, "Feeding the Planet, Energy for Life," the 959-sm (10,320-sf) pavilion reimagines a traditional Chinese Shitang (dining hall). The sinuous, coiling form contains an exhibition space (designed by Ralph Appelbaum) and rooftop terrace. As the video clip below expresses, Libeskind conceptualized the pavilion relative to traditional Chinese landscape representations. Through this approach, the pavilion "aims to tell the story of civilization, technology and the 21st Century as well as offer a space for reflection and a celebration of different cultures," in Libeskind's words.

Photo: Expo Milano 2015

Two gray concrete stairs wind their way up and through the 12-meter-high (39 feet) pavilion, giving visitors two independent routes through the exhibition and up to the roof terrace. Inside, bamboo armatures support the hundreds of display screens inside. Among other things, the gray and bamboo serve to underline the striking red metalized tile covering the exterior. Red seems to be a preoccupation with Libeskind these days, as his contribution to the Salone del Mobile last month – "Future Flowers" for Oikos – consisted of intersecting lines made from red aluminum panels.

Photo: Hufton + Crow

Photo: Hufton + Crow

Studio Libeskind worked with the structural engineers at Ramboll UK to develop a steel-frame structure for what the engineers call "an almost cork-screw like shape." They used parametric modeling and coding techniques to limit the number of unique structural pieces required – only 25 shapes are used, very few for such a complex form. Additionally, they used digital tools to evaluate the exterior surface in order to reduce the number of unique tiles – 95% of them are a flat, uniform shape, and the rest are a bent at an angle to handle the concave curves, thereby cutting down on the time needed to manufacture the pavilion's skin.

Ground floor plan showing exhibition space

Section through exhibition space, roof terrace, and VIP room between them

Outside of the steel frame is a concrete surface, painted red to match the tiles; this surface makes the exterior watertight and serves as the substructure for the pavilion's skin. A mounting plate was attached in three points to the rods wrapping the exterior, serving as an armature for the 4,200 ceramic tiles. This mounting system, developed by the Engineering Division of Casalgrande Padana, enabled the plates to be adjusted for angle and overlap during construction. Most importantly, this system allowed the tiles to be installed without any visible fasteners.

Construction photos showing mounting plates attached to rods

Construction photo showing attachment of ceramic tiles

Casalgrande Padana's Fractile slabs cover the Vanke Pavilion, a product that dates back to 2013 when Libeskind designed them for the Italian stoneware manufacturer. The slabs adorned his Pinnacle installation in Bologna that year. Then and now, the Fractile slabs are produced with the company's Bios Self-Cleaning technology. Per Casalgrande Padana, "when exposed to sunlight the Pinnacle slabs trigger a reaction that reduces airborne pollutants, decomposes the dirt that settles on the surface, and lets it be washed off by rainwater."